| |

|

Click on a thumbnail picture below to see the full size version.

|

116 Entries.

|

|

Saturday, April 6

|

View Page

|

|

2024 Growing Season

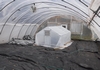

The start of the new season can often overlap with the previous season and this year is no exception. The hoop house was moved about 32ft in anticipation of the 2024 growing season. There were no obvious problems at the last location, but this is the best time to move� before soil issues.

This site was last grown on in 2021 and while it may be a lot of work to make this move the hopeful reduction of disease issues in season justifies this work.

With the demands of the in-season growth the soil must be in good tilth and quality. When growing an intensive crop, it is important to keep this in-mind and practice rotations when ever possible to reduce the chance of issues building up over time. Soil treatments can offer some reduction in issues, but a plant rotation is the best method.

For ease turf grass (Northeast mix) is used as a cover crop as once established it is a monocot and holds moisture well and creates an environment supportive of earthworms that does not require tilling or other soil equipment, just a regular mower to keep the grass at lawn height (about 3.5�) is all that is needed.

Nutrient Management for Cucurbits: https://ucanr.edu/sites/nm/files/76628.pdf

|

|

|

Saturday, April 6

|

View Page

|

|

Initial Site Preparations

Today the focus was on initial site preparations which started off by weed-whacking the grass down to close to soil height. The reason for this is to help make the amendment application and tilling process to come shortly, as easy as possible.

For those interested in proper Cover Crop Management: https://www.sare.org/publications/conservation-tillage-systems-in-the-southeast/chapter-5-cover-crop-management/cover-crop-management/

|

|

|

Saturday, April 6

|

View Page

|

|

Adding Amendments

Here is the line-up of nutrients added to the growing site for this year. While there may be a bag of each shown in the image this does not represent the exact quantity added. For the actual numbers this is calculated with the results of a soil test. However, the list is as follows that was applied over about 1,100sq.ft. of growing space�

-Calcitic lime (50 lb)

-Peat Moss (33 cubic feet added)

-Gypsum (160 lb)

-Sulphate of Potash (0-0-50) (30lb)

Micronutrients

-Ironite (14 lb)

-Borax (1 lb)

-Zinc Sulfate (0.5 lb)

-Manganese Sulfate (3 lb)

-Copper Sulfate (0.5 lb)

While manures can be effective, only leaf-based compost that was added five years ago and has been serving as the base soil amendment. This has increased overall organic matter and since it is in the target range no more has been added. This is part of a new concept being referred to as �Soil-Hydro� (with hydro being short for hydroponics which by definition is grown plants without soil). This odd word choice is used because the idea is that the soil is providing the base substrate to grow the plant and the grower will add in what the plant needs to �eat� during the season much like a hydroponic growing set-up would require.

This Soil-Hydro concept offers the stability of soils buffering capacity along with the depth the giant pumpkins roots can expand along with the added bonus for growers to dial in different nutrients that can be timed with the stage of plant growth creating the best of both worlds.

Soil Management Practice Comparison for yield and quality of pumpkin:

https://www.researchgate.net/publication/350763593_Yield_and_Quality_of_Lettuce_Pumpkin_and_Watermelon_Varieties_Grown_Under_Five_Soil_Management_Practices

|

|

|

Saturday, April 6

|

View Page

|

|

Amendments Successfully Added

This is what the growing space looks like now that the amendments have been added. No time for tilling today, but with the short grass mostly covered it will not regrow very quickly providing time to till at a later date with no negative impacts.

For those that have a tractor here are the top-10 implements recommended to have on hand to make farm life easier� https://tipsnotebook.deere.com/top-10-implements/

|

|

|

Monday, April 8

|

View Page

|

|

Soil Heating Cables

Here is the area (about 5ft. x 5ft. x 1 ft deep) that is where the 40ft soil heating cables will be buried. The soil is initially excavated and then the bottom is pitch forked to increase aeration and water infiltration. Doing this about 12-inbches below the soil surface helps increase drainage and keeps the main starting area on the dryer side which should help mitigate potential issues in this very important area of the plant.

Soil Heating Cables Guide: https://www.frogchorusfarm.com/soilheatingcables.html

|

|

|

Monday, April 8

|

View Page

|

|

Soil Heating Cables Pattern

This shows the basic pattern that is used to lay out the heating cables. While there is an inline thermostat an external one will be used making this exact pattern less important.

Reason for the external thermostat is to not only know what the temperature actually is in the root zone, but to ensure it does not get too hot and is under a reliable controller. In the past the inline thermostats have failed resulting in plant damage due to overheating of the root zone. This all-in-one live sensor and controller (which will be shown in the future posting) help keep conditions regulated and consistent.

Tips for installation of soil heating cables: https://morelectricheating.com/media/assets/product/documents/Wrap_On_Gro_Quick_Soil_Warming_Heating_Cable_Installation_Instructions.pdf

|

|

|

Monday, April 8

|

View Page

|

|

Initially Holding Cables In-Place

All cables are tested before going into the ground and this not only ensures they are working, but also helps make them easier to bend into the desired pattern. Using some simple bamboo stakes to help with the hair-pin turns and then adding some soil to set them really does make the process easy.

Keep adding more and more soil until all of the cables are covered and then the bamboo stakes can be removed and everything should be just as you left it.

Additional Soil Heating Cable Installation Information: http://www.arctictrace.com/docs/installation-soil-heating.pdf

|

|

|

Monday, April 8

|

View Page

|

|

Soil Heating Cables Installed

If everything is done right, it will look like you did not do anything😉

However, it is important to mark the corners with stakes so when the area is tilled the �no till zone� is evident to prevent damaging what took time to put in place.

|

|

|

Tuesday, April 9

|

View Page

|

|

Progress is Being Made

Taking advantage of a rare non-windy day a lot was accomplished. End wall plastic was put up, the sides insect netting and plastic was also installed. Time also allowed for the top �roof� plastic to be put on and wired in. There was even enough light left in the day to till the area, so productive day, just no time for pictures;-)

Tips for Installing Greenhouse Plastic: https://www.tunnelvisionhoops.com/bloginstall-greenhouse-top-cover/

|

|

|

Tuesday, April 9

|

View Page

|

|

Peroxide Soil Drench

Even though the soil has been rested for two years a peroxide drench was still applied to help reduce any potential carry over issues. This was done after all amendments were added and the entre growing site was tilled. Essentially the soil is �good to go� and then the drench was applied just before planting. Since the peroxide it is most effective in the upper portions of the soil profile as it percolates down, by drenching after the soil is mixed and in place, the peroxide is most active where the roots start and are most likely to be for the season.

Since drenching is done by hand it is important (from the applicator stand point) to ensure that all areas are covered. This is a contact only product so full coverage is essential for effectiveness.

Goal is a 300ppm solution

Procedure Followed�

-Ensure soil has some moisture already present to ensure a quick peculation of the drench in the soil profile

-Applied around sunset since UV light can degrade the product quickly

-1,000sq.ft. is drenched with about 275 gallons of water

-3 gallons of peroxide are added to the water tank immediately before application

-Entire area is drenched twice over to help ensure complete coverage

Scientific Articles:

https://openurl.ebsco.com/EPDB%3Agcd%3A11%3A8008603/detailv2?sid=ebsco%3Aplink%3Ascholar&id=ebsco%3Agcd%3A136081950&crl=c

https://academic.oup.com/jambio/article-abstract/121/2/519/6717265

|

|

|

Wednesday, April 10

|

View Page

|

|

Seed Starting Day: Chosen Seed 2287 Sadiq 2022

Only growing one plant make seed selection this much more important. In the end what it comes down to is what do you have confidence in as if you are not happy with the seed you are not going to put in the full effort these plants require.

Since this plant will be going in a hoop-house knowing this seed came from Utah where the normal outdoor conditions are like a hoop-house the hope is this will do well in the structure. Time will tell on this, but this was the thought process behind the selection.

Older video, but core content is the same: YouTube

|

|

|

Friday, April 12

|

View Page

|

|

Seedling Starting Mix

While there has been some early iron deficiency noticed in years past, there was the curiosity if it was the starting material. So, to test this theory, this year Sungro Black Gold was selected to use as the seed starting mix. It has a nice consistency to it and other growers report success with it. There is nothing wrong with this mix and the fact that is comes in a small bag is easy for growers to use what they need for the seasons and get a fresh batch for next year.

However, seeing how the seedling progressed this year, it seems the iron deficiency seen in the plants is not related to the starting mix and it may be related to the early season peroxide drench that is done to the soil. Luckily it can be corrected with some iron fertilizer applications, just something to add to the early season list to increase odds of success.

Interesting Potting Soils Comparison Video: YouTube one has the Black Gold in the line-up: https://www.youtube.com/watch?v=SBrsdGWNhxU

|

|

|

Sunday, April 21

|

View Page

|

|

Cold Frame Inside Hoop-House

While growers often use terms like cold-frame, greenhouse, and hoop-house interchangeably, each has their own definition and meaning. The terms will be kept consistent here in hopes to avoid potential confusion.

The reason for this additional cold-frame is to help increase control over the environment immediately around the pumpkin plant in the early stages of growth. Since the plant is small and heat is a needed, keeping the area small helps to increase heating efficiencies.

The overall dimensions of this structure is 8ft. wide and 12ft. long and 6ft. tall at the peak. The width and length were specifically chosen to match the size of an early growing pumpkin plant with the goal being once the secondary vines touch the sides, the main vine should be touching the end wall.

As a result, this is custom build to ensure it is dialed in for pumpkins. The connectors are galvanized outdoor tent connectors and the main supportive material is fencing top-rail. It is then covered in IR 6mil. greenhouse polyethylene that is held in with U-channel and wiggle wire. There are two access doors at each end and also since this is already in a structure the sides are also able to easily lift up for side access if needed.

*IR Poly = InfraRed and AntiCondensate plastic film. This prevents water droplets from building up on the inside layer. Water droplets may reduce sunshine penetration by as much as 20%. The IR additive seals in infrared energy, assuring warmer night temperatures in the air, soil, and plant tissue in the greenhouse.

However, there are more custom features added that will be described in the following posts�

Scientific Article: �Testing of the condensation characteristics and light transmissions of different plastic film covering materials�

https://web.archive.org/web/20170809035646id_/http://moritz.botany.ut.ee/~olli/b/Cemek05.pdf

|

|

|

Sunday, April 21

|

View Page

|

|

Custom Control Center Tote

In an effort to keep things organized (controllers and cords) a large heavy duty plastic tote was purchased and the controllers were attached to the outside for easy reading of conditions. This also allowed the inside to contain all of the cords and the lid kept the area sealed off. While the total inside volume was not needed the height was especially for the CO2 controller.

Having everything in one location made it easy to get a full check on the environmental conditions and make adjustments if needed. This not only helped increase efficiency but also made installation and take down very simple since this is only a temporary structure.

Tote Used �Rubbermaid 18gal Roughneck Storage Tote Gray�

https://www.lowes.com/pd/Rubbermaid-Commercial-Products-Gray-Tote-with-Lid/1000389261

|

|

|

Sunday, April 21

|

View Page

|

|

Soil Heating Cable Controller and Above Ground Reptile Heat Lamp Controller

The image may be slightly out of focus and the values can be read, but the key is the application of these two controllers. The �Jump Start� one on the right has the temperature sensor about 8� below ground to get a reading of the root zone temperature. This is typically set for 70F (21C) and takes about three days to reach this temperature, after this time it just needs to maintain this heat. As a result, this is set-up ahead of the plant going in the ground as a way to check to make sure things is working properly and to ensure the seedling can start growing from day one of transplanting.

Scientific Article:

https://academic.oup.com/jambio/article-abstract/121/2/519/6717265

The �Hydrofarm� controller is essentially the same as the other one, except the sensor is about 8� above ground and senses the air temperature. This one is set for 68F (20C) as having it a little cooler than the root zone can promote more vigorous rooting. This controller is connected to three 100-watt reptile heat lamps that emit heat with no light to not alter the photoperiod of the plant. On cold nights the plant and heaters are covered with a white sheet (that will later go on the pumpkin if all goes well) to vastly increase the heating efficiency.

Scientific Figure Comparing Air and Root Zone Temp for Lettuce:

https://www.researchgate.net/figure/Lettuce-Lactuca-sativa-L-var-longifolia-grown-under-different-growth-temperature_fig2_358625089

|

|

|

Sunday, April 21

|

View Page

|

|

Cold Frame Vent + Fan Thermostat and Light Controller Timer

The gray PECO thermostat with the metal coils is sensing the air temperature and even though it is an analog version this is perfectly fine. It does need to be set in relation to the other digital thermostat present so they do not work against one another as this one is responsible for cooling and not heating. When this senses the air temperature has reached about 86F (30C) it will turn on an exhaust fan and open a vent. This allows for cooling of the cold frame by moving air. This is also dialed in to work with a similar (but larger) ventilation system for the larger hoop-house structure.

However, when the venting system for the cold-frame is activated the CO2 system can sense this and goes into idle mode so the CO2 is not wasted by being vented out of the structure. Once the venting system turns off, the CO2 system will reactivate and start dosing CO2 again as the vents will be closed.

Scientific Article �Effect of Vent Openings and Insect Screens on Greenhouse Ventilation� :

https://www.researchgate.net/publication/222921589_Effect_of_Vent_Openings_and_Insect_Screens_on_Greenhouse_Ventilation

|

|

|

Sunday, April 21

|

View Page

|

|

CO2 Controller (Titan Controls Atlas 8) Reading: 1050ppm

After demonstrating the improvements to plant growth that CO2 enrichment can provide this is something that is a key part of plant growing (assuming other conditions are being maximized). This controller is one that is used from day one of planting until the pumpkin is about 30 days old or so. CO2 enrichment does not improve pumpkin growth (probably because they are mostly water) but it does help improve plant and root growth.

The reason why the day 30 pumpkin growth is not a hard date for CO2 removal is because it does not have to do with the pumpkin itself but more of the plant growth. CO2 is beneficial to plant growth so typically around day 30 for the pumpkin, the plant (at least in my case) is near full size (1,000sq.ft.) so the CO2 is no longer needed.

The target level is about 1,100 ppm and in this early part of the season a 50 lb CO2 bottle will last about one month, compared to the main growing season that same bottle set to the same level will only last 7-10 days.

An advantage of this controller is it can sense when power is sent via the cooling thermostat and will go into an idle mode where it will still provide live readings of the CO2 in the area, but not actively add any until the vents and fans turn off. Then it will add CO2 until the target level is reached.

Article About CO2 in Greenhouse production from 1993:

https://hortscans.ces.ncsu.edu/uploads/c/a/carbon_d_52570d1851c70.pdf

|

|

|

Sunday, April 21

|

View Page

|

|

Supplemental CMH Light (Part 1 of 2)

The green timer is attached to the 315-watt CMH (Ceramic Metal Halide) grow light with a 4200K daylight bulb in it. This comes on at 4am then off at 9am and then back on at 6pm and off at 10pm. This serves two important tasks�

1. It adds light to increase the plants perceived photo period to replicate late June. This not only helps with speeding up the plant growth rate, but also allows the CO2 to be added for a longer period of time since there is a photo sensor on the sensor that will only add CO2 when there is enough light that the plants can use CO2, since it cannot be utilize during the �night� or dark portion of the day.

2. Most growers will wonder why LED lights are not being used, why has a CMH light been selected? This is because CMH will generate more heat and can be spaced higher from the plant to increase coverage area and allow more natural sun to reach the plant when the light is off during the day. The heat is a good thing early in the season and the more heat the better as this can warm the leaf up also increasing the photosynthetic rate making extra use of the elevated CO2 levels. Also, the increase in spacing from light fixture to plant is nice so there is less shade during the day when the sun is out and the artificial light is off.

YouTube Video Link �CMH Lighting Option� : YouTube

|

|

|

Sunday, April 21

|

View Page

|

|

Supplemental CMH Light Part 2 of 2)

LED lights need to be kept close to the plant to have high PAR (intensity) values and this can cause a shading effect when they are off and the sun is out. Also, the reduced heat they produce is a drawback this time of year as heat is something that is being added anyway so to have it as part of the light, as is the case with the CMH light is an added benefit.

Many will argue that the LED light spectrum is �better� or customizable. To these points, remember this is an outdoor plant that is getting mainly sun and the light is only supplementing light to increase the duration of light exposure. There are some bulb options to get a general spectrum and the 4200K is a daylight/sunlight spectrum.

Also, the customized spectrum sounds great, but the �ideal� light spectrum pattern is not really known so it may feel nice to have dials to adjust, but the adjustments are more of a grower feel good option than increasing plant performance. However, there is active research in this area, so hopefully going forward a more scientific approach to light spectrums and plant performance can be made.

Sure, LED's will be the future, but for now a CMH would be preferred.

YouTube Video Link �CMH Lighting Option� : YouTube

|

|

|

Sunday, April 21

|

View Page

|

|

Planting Day for the 2287 Sadiq '22

This is only about 11 days after initially filing the seed and it could have gone in a little earlier, but there were some very cold nights recently. Those nights were used to test the system to ensure sufficient heat could be maintained and no failures occurred and no breakers were popped.

Everything passed inspection so now, the seedling is in the ground with all the special environmental additions as well.

This is a little more efficient method of seedling planting�

YouTube

|

|

|

Sunday, April 21

|

View Page

|

|

CO2 Sensor and Heater Placement Around the 2287 Sadiq '22

Here the placement of the reptile heat lamps and the CO2 sensor can be seen. The triangle of heaters ensures all angle are covered along with the air temperature sensor being placed in the middle and above the plant. Out of the image is a small fan to keep air circulation which is both important for the heat but also the CO2.

Above the plant is where the CMH light is located but it is off at this time. Also, the weed block helps reduce the need for weeding and keeps soil moisture retained but still allows for air exchange.

Carbon Dioxide Sensor Placement Options: YouTube

|

|

|

Sunday, April 21

|

View Page

|

|

Full Set-up Daytime Image: 2287 Sadiq '22

This provides a general overview of the support system around the seedling so while there may be a lot going on (see previous posts for details) everything serves a purpose and is part of a complete system to maximize efficiencies and plant growth.

The large black cord that seems to be in the middle of the image is going to the CMH light that is located directly above the seedling to help add some heat and increase the photoperiod.

While it may not be as intense as a grow tent set-up this shows how detailed it could get :

https://hydrobuilder.com/learn/grow-tent-setup-guide/

|

|

|

Sunday, April 21

|

View Page

|

|

Full Set-up Nighttime Image: 2287 Sadiq '22

This is the same set-up and general camera angle as the previous entry, but it shows the light coverage area. While the seedling is small at this early stage, the light is set-up so the plant as it vines will still be exposed to the high intensity light. The CO2 sensor is also kept near by since it has a photosensor so the goal is to ensure the CO2 is being added when the plant can photosynthesize.

Article Link �Determining Grow Light Position Using a PAR Meter� :

https://www.apogeeinstruments.com/blog/determining-grow-light-position-using-a-par-meter/

|

|

|

Sunday, April 21

|

View Page

|

|

Night Time Extra Coverage

To help keep as much heat trapped inside the structure as possible and two old boat tarps are used to cover the cold frame to help act as a thermal barrier. Blankets will also be put on first and then the tarp to really help minimize the potential heat loss.

These are removed in the morning to allow natural sun to be exposed to the plant when the artificial light is off and cooling becomes a greater concern.

While there are different greenhouse covering material to consider with the light transmission and U-values, the simple boat tarp is easily available and does the job that is needed. However, the link below shows some of the details on the different options available.

Article Link � Energy Efficient in Greenhouses�:

https://farm-energy.extension.org/wp-content/uploads/2019/04/2.-A3907-01.pdf

|

|

|

Monday, April 29

|

View Page

|

|

Night Time Temperature Readings

At night due to the longer exposure time, it is a little easier to capture the numbers on the thermostats so this shows�

�Jump Start� = Soil Temperature of 71.4F (21.9C)

�Hydrofarm� = Air Temperature of 73.4F (23C)

These are right around the target levels so all is good here.

22C (71.6F) Night time temperature seems to offer the highest yields in this cucumber study

https://www.researchgate.net/publication/308885563_Night_time_temperature_and_day_time_irradiance_on_photosynthesis_and_growth_of_cucumber_Potential_and_possibilities_for_energy_saving

|

|

|

Monday, April 29

|

View Page

|

|

CO2 Reading

With the target of 1,100ppm of CO2 seeing the live readout at 1,091ppm is demonstrating that everything is in the target range. Even though it is dark outside, with the artificial light running the CO2 will continue to be added as the sensor knows the plant can photosynthesize therefore it can actually use and benefit from the CO2 addition.

Article About Carbon Dioxide Supplementation:

https://extension.okstate.edu/fact-sheets/greenhouse-carbon-dioxide-supplementation.html

|

|

|

Monday, April 29

|

View Page

|

|

Iron Deficiency: 2287 Sadiq '22

Just like last year this is another image what an iron deficiency looks like in a giant pumpkin plant. This image was taken at night under the artificial light as it shows the color distinction better.

Iron deficiency is evident by the newer growth turning a faint green to yellow in extreme cases. This was identified early so iron fertilizer was added to lessen the extreme case that this would show.

Last year the plant was a more advanced deficiency�

http://www.bigpumpkins.com/Diary/DiaryViewOne.asp?eid=339841

Recognizing and Treating Iron deficiency:

https://extension.arizona.edu/sites/extension.arizona.edu/files/pubs/az1415.pdf

|

|

|

Friday, May 10

|

View Page

|

|

Biomin Iron (Rate 1oz. per gallon) to Correct Deficiency

While there are many different types of Iron fertilizers the Biomin line uses and amino acid to help increase the amount of the nutrient that is plant available. For many of the micronutrients this is important as they are needed in small amounts but can often be a challenge to get the plant to uptake. Having this form allows for directed applications to be readily absorbed by the plant to help reduce the duration of a deficiency.

Typically, when a deficiency is seen in a plant it will take multiple applications of the deficient nutrient to correct the issue. This is so the risk of plant damage is minimized and to help the plant continually pick-up some of the nutrient. This also provides the grower the ability to make changes based on the plant response to avoid the chance from going from deficiency to toxicity.

There were a total of six Biomin Iron applications made at the rate of 1oz. per gallon. The following dates correlate with the six applications� April 20th, April 27th, April 29th, May 1st, May 3rd, May 6th

Once the deficiency was corrected the plant did not need any more applications based on the visual appearance of the leaves. So, in this case it was simply an early season only issue. So, directed applications at this critical time can help the plant tremendously later in the season.

Iron Fertilizer Sources:

https://extension.okstate.edu/fact-sheets/identifying-and-correcting-iron-deficiencies-in-ornamentals.html

|

|

|

Sunday, May 12

|

View Page

|

|

2287 Sadiq '22 Starting to Vine Out

This shows the plant on the ground and running. What is key is that the secondaries are also starting to stretch out and it looks like the ratio of the main vine to the side vines is matching what was predicted when it came to planning this cold frame.

The main vines does grow on weed block that that is unrolled as the vine grows. This is a thinner material than the darker material that has the blue strips on it. Even though it is not as thick and tough it is intended to be only used for a season and does a good job of blocking the weeds. While blocking the weeds is great, so is the soil to vine separation that occurs and it also provides a great way to easily check the main vine during the season.

Effect of Plastic Mulch on Growth and Yield of Chilli :

https://web.archive.org/web/20180729010845id_/http://www.scielo.br/pdf/babt/v54n2/v54n2a14.pdf

|

|

|

Sunday, May 12

|

View Page

|

|

Passive Intake Vent on Cold Frame

This show the passive vent that is connected to a thermostat set to open when the inside temperature reaches 86F (30C). At the same time the exhaust fan (seen in the distance) is also turned on allowing for air to be pulled through the structure. The CMH lights are also placed in this direct air flow to keep them cool if needed, but often they are not on during the heat of the day.

The thermostat not only turns on the vent and fan, but at the same time the CO2 controller will go into stand-by mode. This is a great feature as it not only saves the dosing of CO2 when air is being vented out, but it will still monitor current CO2 levels. If air circulation is not sufficient around the plant there will be a reading of less than 400ppm so checking on the CO2 level during the heat of the day is another way to monitor environmental conditions and make adjustments if needed.

A Review of Ventilation and Cooling Technologies in Agricultural Greenhouse Application :

https://www.ijee.net/article_64325_ed4445b59a403b945cb9d541465c6a5f.pdf

|

|

|

Saturday, May 18

|

View Page

|

|

2287 Sadiq '22 Has Outgrown The Cold Frame

The 8ft wide by 12ft long (and 6ft tall) structure is the ideal ratio as when the main vine hits the end of the cold frame so did the secondary vines. The plant was held in for a day or two longer than ideal, due to the cold nights and the ease of being able to heat and monitor the smaller area.

However, today is the day the cold frame needs to come down so the plant can be properly buried and prepared for the Christmas tree/ Box style of pruning that will be used as the plant fills the growing area.

With the CMH lights on the advantage of using two 315watt lights compared to one 630watt lights is better coverage area. Each light is on a light hanger so its height and horizontal spacing can easily be adjusted. Each will cover about 4ft. x 4ft square of plant area. These are again sized to properly fit in the cold frame to maximize the growing area optimization.

There are different bulb options and since these are more of a supplemental light and not relied on to actual grow the plant under the exact spectrum is less of an exact concern since the plant will receive mostly natural sunlight. However, the sunlight bulb (4200K) is what is selected for its higher blue spectrum to reduce the tendency of the plant to stretch and to replicate the spectrum it will be naturally receiving anyway.

630 and 315 watt CMH Review : YouTube

|

|

|

Saturday, May 18

|

View Page

|

|

2287 Sadiq '22 Secondary Vines Climbing the Walls

This shows that the plant could have been removed a few days earlier but it was held in here a little longer due to the cold nights predicted. What this image also shows is the high humidity in this growing space. While plant growth, structure, color and overall performance are all in-line with what would be expected with a competitive plant, humidity is something that growers may need to take into greater consideration. It is not as easy to control as growers may think, but it is a growing environment condition that will be of greater focus this year for sure.

Temperature and leaf wetness can lead to increased disease pressure and also impact growth of the plant. Getting these dialed in is a continual struggle over the growing season due to the ever changing weather and general conditions.

One disease of high concern for Cucurbits is Downy Mildew, for which there are different strains that can impact different members of the cucurbit family with varying severity. It is of the greatest concern to cucumber growers, but here is a study showing how temperature and leaf wetness impact the sporangia germination and infection of Cucurbits�

Interactive Effects of Temperature and Leaf Wetness Duration on Sporangia Germination and Infection of Cucurbit Hosts by Pseudoperonospora cubensis :

https://apsjournals.apsnet.org/doi/epdf/10.1094/PDIS-07-11-0560

|

|

|

Saturday, May 18

|

View Page

|

|

Cold Frame Basic Design and the 2287 Sadiq '22

After removing the 6mil main cover the basic supportive structure and plant can be better seen.

The proportions of the plant and the structure are what is needed to maximize space and not have extra (wasted) space when it comes to heating, cooling and enriching with CO2. With the customization of the design, it could have been made larger but once a plant reaches this size it is typically growing exponentially. With the rate of plant growth at this size/age even if the cold frame was made bigger it would not hold the plant for much longer anyway and the controls over the environment would be even more difficult to regulate.

So, this is the ideal size to help the plant get a good early start and not be overly difficult to manage the heating and cooling. If other plants were the selected crop to be grown other dimensions may be ideal, so this is purposely set for giant pumpkins.

These are the fittings used along with regular fence top-rail for the pipes� High Peak Canopy Fittings:

https://canopiesandtarps.com/canopy-fittings.html

|

|

|

Saturday, May 18

|

View Page

|

|

2287 Sadiq '22 Exhaust Fan End Wall Removed

Removing the structure alone does present a little bit of a challenge and a little stress but this was part of the design features. While the end wall detaches the ridge pipe is attached in a fix location so it cannot fall on the plant. By removing the side pipes the end wall can be cleared from the plant. During the design and development stages of the cold frame this modification was made to help reduce the chance of plant damage.

Selecting the correct size vent and fan is important for the larger and also this smaller structure. It can come down to CFM (Cubic Feet per Minute) with a few considerations to take into account. For this purpose, a 24� shutter vent and a 16� fan were selected. The fan had three speeds, but needed to only be run on the slowest speed as everything seemed to be calculated to work out well.

Here is a link to a Greenhouse Fan Size Calculator :

https://www.acfgreenhouses.com/greenhouse-fan-calculator.aspx

|

|

|

Saturday, May 18

|

View Page

|

|

2287 Sadiq '22 With Cold Frame Fully Removed

While there may still need to be some details completed, this shows the cold frame structure fully removed and the plant ready to fill its new growing area. The lights have been transferred from the cold frame to a 10ft metal pipe that is attached to the larger hoops of the hoop house which can be also be adjusted with light hangers. (The pipe can move and so can the lights on the pipe.) Having these still over the plant allow for a lengthening of the photoperiod and also DLI (Daily Light Integral) but despite these being official grow lights they still do not cover that much are with high intensity light.

The goal is to make the plant think that it is more like Jume 18th and not May 18th when it comes to the duration of light the plant is receiving.

Daily Light Integral (DLI) : YouTube

|

|

|

Tuesday, May 21

|

View Page

|

|

Vine Burying

When it comes to vine burying the process is best kept simple. As the secondary vine grows out about 2ft. (60cm) the vine is lifted and then a shallow trench is dug under it that the vine will lay in. It is about 3 inches (7.5cm) deep so the vine can be covered with enough of the soil that was removed to create the trench so the top node is covered where the root will form. Blocking the light and keeping the area moist can help encourage the roots to form, but adding a rooting hormone can help this process along as well.

However, before burying the vine, the tendrils are kinked/broken if needed, and CloneX gel is applied (*Not sponsored by CloneX) to both the top and bottom are where the root will first start to grow from. This is a rooting hormone that will help encourage the initiation of the root and also help the root to branch once it starts growing to help increase the surface area of the root.

A small paint brush is used to apply a large drop on the root nodes that can be seen in the image. CloneX is used for its ease of application, effective results and the fact that one 250ml bottle will do a full sized (1,000sq.ft. plant) for the season.

It may take a little extra time, but in the end it is worth it.

CloneX does contain Indole Butyric Acid (IBA) as its main active ingredient�

Indole-3-butyric acid in plants: occurrence, synthesis, metabolism and transport :

https://onlinelibrary.wiley.com/doi/abs/10.1111/j.1399-3054.1993.tb05513.x

|

|

|

Tuesday, May 21

|

View Page

|

|

Rooting Hormone Comparison

While this may be from a pervious growing season it shows the difference that a node that has had CloneX gel (*Not sponsored by CloneX) applied compared to one that has not had it applied look after a short period of time.

The key is the quicker rooting and also the increase in branching which helps with the surface area to volume ratio leading to improved water and nutrient absorption.

This image shows a vine that was not left long enough to have the top root start to form, but this is intended to show the speed of rooting and the increase in branching that does occur.

Here is how the main ingredient (Indole Butyric Acid (IBA) impact tomato cuttings�

Effect of Indole Butyric Acid (IBA) on Early Root Formation(Tomato �Sahil� Hybrid) Cuttings :

https://www.jmaterenvironsci.com/Document/vol6/vol6_N1/33-JMES-1311-2014-Waheed.pdf

|

|

|

Tuesday, May 21

|

View Page

|

|

Effectiveness of Rooting Hormone

This section the vine lifted slightly which allows for a great view of the branching of the bottom root, but also the top root also has developed enough to reach the soil as well. When the vine is buried and parallel with the ground the top root does not have as far to travel before it finds the soil. While this image shows a �not ideal situation� still demonstrates that the method of adding a rooting hormone can be effective.

Exogenous auxin improves root morphology and restores growth of grafted cucumber seedlings:

https://www.researchgate.net/profile/Astrit-Balliu/publication/316895757_Exogenous_auxin_improves_root_morphology_and_restores_growth_of_grafted_cucumber_seedlings/links/59194d65aca27200fe52fb1f/Exogenous-auxin-improves-root-morphology-and-restores-growth-of-grafted-cucumber-seedlings.pdf?_sg%5B0%5D=started_experiment_milestone&origin=journalDetail

|

|

|

Monday, May 27

|

View Page

|

|

Soil Moisture Sensors (WaterScout SM100)

There are many options when it comes to monitoring equipment and as growers looking at the options and making a decision on what will work best in their situation is important. For some it may be the features for others remote connection may be important, but regardless of what is selected the proper set-up is a very important step that is often over looked. When using a device to guide other decisions it is important to get accurate and repeatable data.

Inaccurate data is worse than no data at all. So, ensuring the proper set-up protocol is followed to provide not only accurate results but ones that are repeatable season to season.

The Spectrum Technologies WaterScout SM100 sensors and data logger is the combination selected for soil moisture monitoring. This is a professional set-up that is about 6+ years old and has only needed battery replacements over this time.

WaterScout SM100 : YouTube

|

|

|

Monday, May 27

|

View Page

|

|

Consistent Sensor Depth (About 6 inches or 15cm)

Since three soil moisture sensors will be placed around this plant it is important that each is at the same depth so fair comparisons can be made. While the exact depth is open for some debate 6 inches (15cm) was selected as this marks a good depth of the same growing substrate/compost mix.

Also since drip tape is the main source of irrigation the sensors are also installed half way between the lines. In addition, there will also be a tall bamboo stake placed near the spot the sensor is buried to not only make it easier to find but to know where the data is coming from.

WaterScout SM100 Sensors

https://www.specmeters.com/brands/waterscout/sm100/

|

|

|

Monday, May 27

|

View Page

|

|

Sensor Installation

The proper method of installation is important and while it may not seem like there is much to it or how many different ways can there be, but there are actually many options. However, the correct procedure is to cut the soil profile and insert the probe in undisturbed soil so the sensor surface is vertical to avoid water accumulation which could lead to a false reading. Also, making sure the cord is also horizontal will help avoid water from running down the cord to again provide a false reading. It is this attention to detail that many growers neglect to take into consideration as they only want to look at the resulting numbers. But if these steps are not followed, the reading may not be accurate.

There is also a brown bamboo stake on the right-hand side (more on that in the next post).

Also, many growers may not realize exactly how water moves through a soil profile so here is a video that shows a Sand loam, Loam and clay loam soil profile and how water moves through it over time�

How Water Travels Through a Soil Profile : YouTube

|

|

|

Monday, May 27

|

View Page

|

|

Soil Moisture Sensors Placement Marked

There are multiple reasons for the large bamboo stakes marking the exact placement of the soil moisture sensors�

1.) To know exactly where they are so they are easy to locate if needed

2.) As the plant grows out and over the areas the location of the data can easily be identified

3.) If there is a problem there will not need to be any searching for the location

4.) Comparisons of the plant to readouts can be easily be made

*It is important to also let the sensors sit for a period of time (about a week) before taking readings. The reason for this is the soil has been disturbed so letting everything settle and saturate is important to ensure reliable and consistent readings that can be used as a comparison.

The colors match the colors on the data logging box so having a redundant system to ensure the location of the readings is important. The locations were carefully selected to ensure maximum spacing between each so there is not a chance of interference from one sensor to another.

Also, the orange one is in the older portions of the plant, the green one is near the pumpkin and the brown one is in the younger plant material. This way different sections of plant age can be compared during the growing season. The drip tapes each have independent valves so custom adjustments can be made if needed.

If you want more information than you may think is possible so placing soil sensors here is an article� Impact of sensor placement in soil water estimation: A real-case study :

https://www.researchgate.net/publication/359227874_Impact_of_sensor_placement_in_soil_water_estimation_A_real-case_study

|

|

|

Monday, May 27

|

View Page

|

|

2287 Sadiq '22 Plant Overview

The umbrella is shading the early female flowers that may be a potential keeper. By providing early shade this reduce the chance of the main vine tip burning or the early female flower development from having heat related damage. Since the flowers does a lot of differentiation and development on the cellular level even before it opens for pollen, the protection before the flower opens is important. This may help reduce the chance of aborts.

Many growers only start to offer protection on pollination day and beyond, but the early protection is also important and the umbrella method is quick and easy. It can also be moved if a flower further down the vine is the new chosen one. However, if you are growing outside make sure it is on a sturdy stake so the wind can not damage this critical area of the plant. How strong of a stake?... Strong enough so the fabric of the umbrella would tear before the stake breaks, so metal stakes it is😉

The area is 32ft. wide and the plant can grow about 35ft. long (structure is 40ft. long). The black weed block fabric is porous so it can allow water to drain through it, but it also helps hold in soil moisture and is does save a lot of work not early season weeding. Once the plant grows out the material is rolled back and then the shade of the leaves also will suppress weed formation.

The black lines/cords are one of three things� (each described in more detail on the next post)�

1.) CO2 Rain Tubing

2.) CO2 Sensor

3.) Humidity Sensor

While this is intended for indoor operations this explains the rain tubing�

Using Rain Tubing for Carbon Dioxide Delivery : YouTube

|

|

|

Monday, May 27

|

View Page

|

|

Mid-day Readings May 27th, 2024

This just shows a point in time reading in the middle portion of the day. The �Acurite� reader does log the min and max humidity and temperature over the last 24-hours but placement can be a challenge especially when the sun is out. (Cloudy days it is more accurate.)

The CO2 control does only read 449ppm, because the fan has been on and the system is in idle mode so it is still providing readings, but no active dosing at this time. Once the fan turns off and the vents close the system will go back to active dosing while it is light out to reach the target of 1,100 ppm.

Humidity = 60% (Range 43%-99%)

Temperature = 88F (Range 68F-93F)

To get these readings there are three key components�

1.) CO2 Rain Tubing- 1/8� black tubing with a pin hole every 12� that forms a 100ft. loop where the CO2 is injected on the ground. Since most of the stomata are on the underside of the leaves.

2.) CO2 Sensor- The cord is 15ft. long so it is placed as close to the plant but there is a gap since the plant is small. However, it still provides accurate readings especially since CO2 is heavier than air so it will drift to the plant anyway. The use of fans does help avoid high CO2 pockets as well.

3.) Humidity Sensor- The sensor is directly below the CO2 one so the same physical location is where the data is all coming from for now.

Full control over all conditions is not possible, the conditions provided here are in the target ranges. (Under �ideal� conditions the minimum humidity level would be raised by about 10%.)

This article stresses the importance of water when it comes to cucurbits dealing with heat stress�

Effect of climate change on the production of Cucurbitaceae species in North African countries :

https://www.researchgate.net publication/373051566_Effect_of_climate_change_on_the_production_of_Cucurbitaceae_species_in_North_African_countries

|

|

|

Sunday, June 2

|

View Page

|

|

Irrigation: Incoming Water Complete Set-up

In the image there is one main water line coming in and then it is split into two separate lines each with a DIG timer. In short one is connected to the drip tapes early in the season and once removed the other one becomes active to fill the irrigation water tank.

While the two timers each have a different intended purpose for their current use either is working out just fine, but you can check out each with the manuals provided below and see the next post on how each is being used.

710A : https://www.digcorp.com/professional-irrigation-products/710a-series-battery-operated-controller/

710AP : https://www.digcorp.com/professional-irrigation-products/710ap-series-battery-operated-propagation-controller/

|

|

|

Sunday, June 2

|

View Page

|

|

Irrigation: Timers

The left-hand splitter goes to a Y-splitter with one hose (marked in orange) going to a �live� as needed hose for when water is needed �now� for whatever reason. The other splitter goes to a 10psi pressure reducer and then a DIG 710A timer. This is a standard timer (compared to the other one) and uses regular city water to irrigate the entire hoop house early in the season until about pollination time. The reason for irrigation of the full structure is when areas are not irrigated the soil and peat (that was added earlier in the season) can become hydrophobic and present many challenges to rewet. So, this timer is connected directly to the drip tapes and is used from the time the structure goes up until about pumpkin pollination time (since no fertilizers are added during this time).

The right-hand slide goes to a DIG 710AP timer is technically a propagation timer so it has some different features beneficial to growers propagating plants which means is has a repeat cycle function. However, when originally purchased this was used to control the mist system, but this proved to be inefficient so there is a new system installed (more on this later) that is fed via the orange and white black hose that can be seen in the lower right corner. The timer now does not connect to the drip tapes, but to the 275-gallon water tank and this timer is responsible for filling the tank.

Having each timer dedicated to one task may seem a bit odd, but this was used originally for a slightly different irrigation set-up but has now been repurposed to this current and more efficient configuration. Also, it does offer the advantage that if a timer was to fail in-season a quick hose change and reprogram of the other timer can have the system back to normal in about 10min. so there is not plant irrigation interruptions as the issue is analyzed and corrected.

DIG Controller Model Comparison : https://www.digcorp.com/controller-comparison/

|

|

|

Sunday, June 2

|

View Page

|

|

Irrigation: Outgoing Water

Here is the irrigation system that connected directly to the drip tapes and is used basically right around pollination time until the end of the season. Reason for this time frame is this is when fertilizers will be added and this tank-based system makes this process easier.

First off, this set-up is sitting on a 275-gallon water tank and there is a tarp over the area to help keep it shaded, relatively cool and protected from the direct rain.

The large pump is a 1hp Wayne Water pump (Model #PLS100) which has an intake hose with a foot valve going into the tank.

Above the tank is a BACO-ENG 1� Electrical Ball Valve that is normally closed and when power is added it will open. This had to be added since even though the pump would turn off, slowly over the day water would syphon out and over water the plants.

Both the water pump and valve are connected to a Woods 50015WD Outdoor Digital Timer. This has two outlets so the pump and valve are both controlled at the same time.

Wayne Water Pump Manual : https://www.waynepumps.com/wp-content/uploads/woocommerce_uploads/2018/10/PLS100_650001-001-B_Web.pdf

|

|

|

Sunday, June 2

|

View Page

|

|

Pumpkin Irrigation Set-Up

Then above the valve is a T-fitting so two plants can be irrigated at the same time, but this year only one plant is being grown so just one side is being used. However, each side has a 10psi pressure reducer and then a 200-mesh stainless steel filer before going out to the drip tapes.

The 3-way electrical splitter in the center that seems to be floating is where the timer is connected, but the reason for this addition is there is also a white on/off switch that has a cord plugged into it which goes to a regular fish tank water pump that is in the tank all the time. To help mix in whatever is added to the tank, this pump is turned on to start stirring the tank, then the product is added and the pump runs to help ensure even distribution. Then it is turned off so when the main pump come on it is an even dosing of the product over the irrigation event with no take settling of product.

However, there is one empty outlet� This is where the BlueLabs Guardian water monitor is plugged into when the nutrients are added to ensure the concentration and pH are dialed in. This is only used during the active mixing process as this is stored inside so it is only added at the point of mixing to be sure the proper feed is delivered to the plants.

*What is present but cannot be seen in this image is a Jobe Rojo Float Valve that has a float on it that will prevent the tank from overfilling if the valve is to fail in the open position. This will prevent the water from running all day and over filling the water tank so it is a good fail safe to have in place.

Irrigation frequency and amount affect yield and quality of field-grown melon (Cucumis melo L.). :

https://tinyurl.com/bdze72a9

|

|

|

Sunday, June 2

|

View Page

|

|

275-Gallon Galvanized Steel Panels Water Tank

While 275-gallon water toes are common, if this style can be found this is the one to get. It is a little more expensive since it is completely wrapped in metal which is because it was originally used to transport isopropyl alcohol and the warping is to help avoid light degradation of the product during delivery. As a result these can become �forever� tanks, even when kept outdoors.

From a pumpkin grower's standpoint this offers two advances, the alcohol essentially evaporates so there is no residual in the tank. Most other tanks are marketed as food grade transporters, but this often means oils were used and while food grade, there is will be a long-lasting residue. The light block the metal does prevent the plastic tank inside from degrading in the sun and it also prevents algae from growing with technically no need for any covers. This is covered with a tarp to shade the pump and equipment on top of the tank.

The black arrow indicated 132gallons which is considered �full� when one plant is being grown. About 100gallons will be irrigated and then refilled via the timers seen in previous posts.

Here is what the tank essentially is : https://smithsofthedean.co.uk/product/ibc-tank-1000-litre-new-galvanized/

|

|

|

Sunday, June 2

|

View Page

|

|

Complete Misting System Components

In the past a repeat cycle timer had been used which is commonly for propagation where newly rooting cuttings need the additional humidity to reduce the chance of desiccation and leaf wilt/burning. The downfall noticed with this system is the weather is different and ever changing so if the on/off cycle period is dialed in for one day the next it would either not be enough or excessive the following day. This system has a controller so it can react to the ever changing environment and at least ensure the humidity does not dip below a pre-set minimum.

The Components:

1.) TrolMaster Beta-6 Controller: This has proven to be a great controller that can handle the outdoor environment for multiple seasons. It is easy to set-up and make adjustments and also provides continuous �live� readouts of the current conditions. With any system it may take a little time to figure out the best sensor placement but the unit itself has been great.

2.) Homenote Misting System: This is a 92ft. (28m) misting line with 26 Brass misting nozzles in the white color to try and keep the water as cool as possible.

3.) Homenote Brass Misting Nozzle Plugs: While all of the above equipment is the fun and interesting components, this is a critical part that should also be purchased. It seems the spacing of the nozzles from the stock system are a little close so selectively blocking some of them can ensure the increase in humidity, but not excessively watering the plant area.

Digital Day / Night Humidity Controller : https://www.trolmaster.com/Products/Details/BETA-6

|

|

|

Sunday, June 2

|

View Page

|

|

Critical Humidity/Misting Components

While the white fitting is the actual misting nozzle and is important, do not underestimate the importance of the brass plugs as well. The set-up around the plant will be shown and it is recommended on the initial installation to run all of the nozzles to get an idea of the maximum distribution of mist.

However, there will likely be areas that seem to be excessively watered and could be potential sites of disease development so it is a quick and easy change out from the misting nozzle to the plug�. If you have the plugs on hand. So, be sure to get some of the plugs as it is much easier to block misting fittings than to add them to the system.

Similar Misting System : https://www.holmanindustries.com.au/wp-content/uploads/MK21013-7m-Misting-Kit-Manual.pdf

|

|

|

Sunday, June 2

|

View Page

|

|

TrolMaster Beta-6 Controller:

This is the brains of the misting system that has a sensor placed at the plant site to ensure the reading is coming from the plant and not the location of the sensor which is away from the plant and in a shaded location.

The current �live� reading is 64.0% humidity. The controller is set to come on at about 57% as this seems to be the correct setting after letting the system run for a few days. The scientific target according to the research papers seems to be a minimum of 60% so this is not far off.

This is connected to a BACO-ENG �� Electrical Ball Valve that is normally off. When the controller senses that the humidity has dropped below the target level it will open the valve which will activate the misting system that is connected to a �live� hose. This will remain on until the humidity is at the target level and then it is turned off. This means the system can come on when it needs to and stay off when not needed. Compared to a cycle timer that will come on and off regardless of conditions has helped better regulate the growing environment.

While there is a 200-mesh particulate filter, if the feeding water is hard or high in salts a pre-filter would be recommended to avoid clogging the very small and fine mist nozzles.

TrolMaster Beta-6 Controller Manual :

https://www.trolmaster.com/PDFHtml/BETA-6.html

|

|

|

Sunday, June 2

|

View Page

|

|

Misting System In Action

It is hard to capture the mist since it is so fine as the real goal is to just increase the humidity in the air and not nessiraily get the plant leaves wet, but it happens. If a true fogger was used this would produce an even finer mist but the set-up is more intensive and the overall plant benefit is not much more than what this simple system produces, so the fogger route could not be justified. A little leaf wetness is not bad and can actually be a benefit for the newly growing vine tips to reduce the chance of burning.

If you look in about the 12 o'clock position there is another mister on that shows the coverage of the mist a little better because of the shade line compared to the obvious one in the foreground. The plant has not reached this area, but the goal is to increase the humidity of the general growing space so the mist does not have to come into direct contact with the leaves to be effective.

Sprinkler System Design Guide : https://www.netafimusa.com/bynder/A7CE490A-FDD3-4CF0-BCE27E80CBA1EE49-sprinkler-design-guide.pdf

|

|

|

Sunday, June 2

|

View Page

|

|

Misting Set-up (and more;-)

Around the premier of the plant about 6ft (2m) up the white misting tubing can be seen. This wraps in a U-shape around the plant with the area where the images was taken from not having misters. The large exhaust fan is on this side so they would be less effective and the goal is to have the mist generated on the perimeter and be drafted to the center and toward the cameras position to help increase the humidity/mist coverage using minimal water.

The important plugs are installed in the center portion so the lights do not get any direct mist on them (even though these are off during the day) and also plugs are placed as needed in the 96ft (30m) of tubing around the plant. It generally averages out to about every other mister being purposely plugged. So, of the 26 misting sites there are about 12 plugs used so be sure to purchase some extras.

�and more

In the lower corners fans can be seen (more details on the next post) these are important to ensure under canopy air movement. This is needed since this is a hoop house structure with the only air flow (at the moment) being the vents so the corners and under leaf area can easily become stagnate.

Keeping air moving is important in general but this will also help with distribution of the CO2 that is being added.

Ventilation in Greenhouses : https://www.dpi.nsw.gov.au/agriculture/horticulture/greenhouse/structures-and-technology/ventilation

|

|

|

Sunday, June 2

|

View Page

|

|

Under Plant Air Circulation �Henry Fans�

I call these �Henry Fans� since �Henry-the giant pumpkin grower� from Massachusetts here on bigpumpkins.com recommended them to me. They have worked out great which is why it is great to reach out to the giant pumpkin growing community as they know the unique purposes these plants take to grow so when something comes recommended it has a high rate of success.

Reading all of the different fan styles, hp ratings, features can get a bit confusing but these are ideal for under canopy air circulation.

These carpet drying / blower style fans not only move a lot of air, but are very stable and low profile so they can easily be placed under the leaf canopy.

There are three settings and 1/4hp and they only need to be run on the lowest setting and work out great. There is still a breeze felt about 20ft away (assuming you have good weed control) so the under-canopy air movement is ideal.

Lastly, they are daisy chainable so the number of extension cords needed can be kept to a minimal.

B-Air Vent VP-25 Manual : https://images.thdstatic.com/catalog/pdfImages/90/90f51cc9-f50e-4ef4-9b3b-9dc450456fec.pdf

|

|

|

Sunday, June 2

|

View Page

|

|

�Henry Fans� In Action

This shows the placement of the fans to ensure air is getting under the canopy. Remember to keep the side open as this is the inlet for the air. In addition, the fan is placed on a small board to help with leveling if needed and to create a separation between the fan and the soil and drip tape.

Evaluation of ventilation performance and energy efficiency of greenhouse fans :

https://www.researchgate.net/profile/Richard_Gates/publication/275409742_Evaluation_of_ventilation_performance_and_energy_efficiency_of_greenhouse_fans/links/553bfb960cf2c415bb0b16db.pdf

|

|

|

Monday, June 3

|

View Page

|

|

Road Trip for 2365 Wolf '21 Pollen

While a self-cross is always an option after reaching out to a few growers and finding out that Ron Wallace himself was growing a 2365 Wolf this would make for a great cross at least on paper. When I reached out to him the day before my female flower was going to open to learn he had some pollen he would not need, getting in the car and driving was the next logical step.

Thanks Ron for the pollen and quick patch tour!

There are still a lot of things that need to come together, but this is part of the process so hopefully the plan comes together.

Effects of Long Distance Transportation on Honey Bee Physiology : https://onlinelibrary.wiley.com/doi/epdf/10.1155/2012/193029

|

|

|

Monday, June 3

|

View Page

|

|

2365 Wolf '21 Male Flower Transporter

It may seem easy, just bring the flowers home, but when traveling and the goal to keep the flowers in water while also reducing the chance of tipping over can be quite a challenge. This stacking container system proved effective and ensured no damage to the flowers.

The outside is a standard 5-gallon pail and then progressively smaller buckets are placed inside until the final water pitcher is the inner most container that contains the water and male flowers.

This is a rare, valuable and delicate cargo so care must be taken to ensure it is not damaged.

Pollen transport differs among bees and flies in a human-modified landscape : https://onlinelibrary.wiley.com/doi/epdf/10.1111/j.1472-4642.2011.00757.x

|

|

|

Tuesday, June 4

|

View Page

|

|

2365 Wolf '21 Male Flower in the Morning Sun

Upon arriving home with the flowers from Ron's the water pitcher is placed in a window even though it was dark out. Then the flowers are exposed to the natural rising of the sun in the morning. While they often to do not full open, typically they will at least start to open with this method. This window does get the first sun of the morning.

Overall, this is just a nice image😉

Pollination Problems of Cucurbits :

https://www.missouribotanicalgarden.org/gardens-gardening/your-garden/help-for-the-home-gardener/advice-tips-resources/insects-pests-and-problems/environmental/pollination/pollination-problems-of-cucurbits

|

|

|

Tuesday, June 4

|

View Page

|

|

Warming the 2365 Wolf '21 Male Flowers

When the flowers start to open in the morning sun it is a welcomed sight. However, the anther of the flower (male structure containing the pollen) is evaluated to see how fluffy the pollen is. Often (due to work) the pollen has to transferred before the flower warms up in the sun so a little heat from the hair drier can help this process.

It is important not to blast the pollen with high heat and air velocity. The goal is to just warm the pollen up so heating the pollen involves indirectly heating the pollen. Moving it so warm air is in and around the male flowers is key so the pollen does not dry out.

Often this takes only 2-3min. and when the pollen grains can be seen on the surface and sticking out this is all you need. Just a little way to help hopefully increase the odds of a successful pollination.

The Effect of High Temperature on Pollen Tube Growth of Snake Melon and Cucumber : https://www.researchgate.net/publication/362787974_The_Effect_of_High_Temperature_on_Pollen_Tube_Growth_of_Snake_Melon_and_Cucumber1

|

|

|

Tuesday, June 4

|

View Page

|

|

2365 Wolf '21 Pollen Fluff

This is the pollen fluff that is considered to be ideal. It will allow for easy transfer to the female flowers stigma so this is what you want to see just before pollinating.

The petals are peeled off so there is only the anther and then the goal is to get the pollen on the lower and inner potions of the female flower first. *Remember pollination is an accidental process, the bees are going to the lower center section for the nectar and are accidentally transferring the pollen. It always seems the bees have a high pollination success so this is just replicating nature.

After this section working up to cover the lobes of the female flowers is done, just because there is typically plenty of pollen and from the human perspective it looks good to see all of the pollen everywhere. However, from a botanical perspective start low and centered and work up and out.

*Sorry no publicly available full text could be found for this article only the Abstract�

Effects of pollen-load on fruit yield, seed production and germination in melons, cucumbers and squash : https://www.researchgate.net/publication/288703096_Effects_of_pollen-load_on_fruit_yield_seed_production_and_germination_in_melons_cucumbers_and_squash

|

|

|

Tuesday, June 4

|

View Page

|

|

Pollen Has Been Transferred

Cross = F: 2287 Sadiq '22 x M: 2365 Wolf '21 (from Ron Wallace)

Date = June 4th, 2024

Distance Out = 20ft.

Number of Secondaries Behind the Pumpkin = 21

Lobes = 4

Lobe Symmetry Rating = 9.5/10 (this is a grower discretion rating, looking at the image you may have a different symmetry rating)

This is a great looking female flower with the lobes being very symmetrical which typically means less odds of issues later with shape. While this is not a guarantee of a perfectly symmetrical pumpkin, lobe symmetry is preferred over lobe asymmetry.

The making of giant pumpkins: how selective breeding changed the phloem of Cucurbita maxima from source to sink : https://onlinelibrary.wiley.com/doi/epdf/10.1111/pce.12502

|

|

|

Tuesday, June 4

|

View Page

|

|

2287 Sadiq '22 Plant Overview

Here is what the plant looks like on the day of pollination. Pollinating early is great in theory, but this will only be advantageous if the plant is timed correctly. The growing area is about 32ft wide and 35ft. long and there are a few secondary vines that are being terminated and the recently pollinated flower is under the umbrella that is covered with the white sheet. There is also a fan, rodent ultrasonicator to deter any unwanted visitors and a fan. There are also some sheets of plywood out to ensure everything is off the ground and on a flat surface. This also helps with having a place to be on while avoiding soil compaction.

Test To Investigate The Use Of Ultrasound As An Alternative Means Of Repelling And Eradicating Rodents : http://www.iosrjournals.org/iosr-jeee/Papers/Vol10-issue4/Version-3/O010439193.JEEE%20[ZSEP01].pdf

|

|

|

Thursday, June 6

|

View Page

|

|

Anthesis Application

About 48-hours after pollination �Antheis� was applied to the pumpkin. This is a combination plant hormone spray that is a combination of ethylene and a cytokinin that I went public with back in 2015 after many years of research.

The short summary is that the concentrated hormones are diluted in water and sprayed as a mist on the actual pumpkin 48-hours after pollination. The goal is to not only increase the duration of cell division, but also the rate.

When applied it does seem to have comparatively slower growth until day 37 from a pumpkin that was not sprayed with the hormones. However, the growth is sustained for longer so the long-term benefits are well worth the slightly slower start.

If you are interested in the details here is a full explanation/presentation :

https://drive.google.com/file/d/1seE6LmSlYt1cEgeBsBrHDitukJxSVuz4/view?usp=sharing

|

|

|

Sunday, June 9

|

View Page

|

|

Extra Pumpkin Protection: 5-gallon paint strainer bag and Sonicators

When the entire season is based on basically one pumpkin everything is done to increase the odds of a successful pollination. So, not only is there a double layer of mill fabric, followed by �� plywood then another double layer of mill fabric under the pumpkin but there is also a white sheet over the site and the pumpkin has a 5-gallon paint strainer bag over it. The mesh of the paint strainer bag offer good air circulation and also some additional shade. In addition, there was a bird that somehow got into the hoop house so this just provides another physical line of defense for the random and unexpected circumstance that may occur.

The two ultra-sonicators ensure that mice do not take any interest in this newly constructed shade structure with one small water filled and potentially tasty pumpkin in the center.

Probably over protection, but over protection is favored compared to under protecting.

*Google Translate can help with this one�

Effect of ultrasonic on mouse behavior and its mechanism in rodent repeller : https://xbzrb.hbu.edu.cn/EN/10.3969/j.issn.1000-1565.2022.05.009

|

|

|

Friday, June 14

|

View Page

|

|

Day 10 for the (F: 2287 Sadiq x M: 2365 Wolf '21 (from Ron Wallace))

(only a picture no measurements)

*Setting pumpkins up early is important and this one was on track to curl the blossom end under so I have been working on adjusting it. However, despite knowing that at this age the pumpkin shell is about has hard as a hot ball of butter, I had a case of Trace Adkins pinky and nicked the side of the pumpkin. From the pumpkin stand-point it is not bad, but just an example of grower error and really the only error I feel I have made this season. (�So far😉

Interesting Article that says the best pollinations occurred between 6am and 8am

BREEDING BIOLOGY AND EFFECT OF POLLINATORS ON THE FRUIT CHARACTERISTICS OF CUCUMBER (CUCUMIS SATIVUS L.), CUCURBITACEAE

https://www.researchgate.net/profile/Ekeke-Chimezie/publication/331374613_BREEDING_BIOLOGY_AND_EFFECT_OF_POLLINATORS_ON_THE_FRUIT_CHARACTERISTICS_OF_CUCUMBER_CUCUMIS_SATIVUS_L_CUCURBITACEAE/links/5c766c1e92851c69504412b2/BREEDING-BIOLOGY-AND-EFFECT-OF-POLLINATORS-ON-THE-FRUIT-CHARACTERISTICS-OF-CUCUMBER-CUCUMIS-SATIVUS-L-CUCURBITACEAE.pdf

|

|

|

Friday, June 14

|

View Page

|

|

Chosen One Is Set� Now Fertilizers Can Be Added

Fertilizing the plant will start on day 13 to allow the irrigation set-up to be tested and the plant now having a sink to store the nutrients. This exact day count is not scientifically supported, but typically fertilizer is not added to the water until post pollination.

Up to this point in the season the only fertilizer that has been given was 6 applications of Biomin Iron in late April and Early May for a total of about 15oz total of product actually used or 2.5oz per application.

This is the concept of soil hydroponics with the soil being used the grow the plant and then when it comes to the pumpkin the plant is fed like it is a hydroponic plant where the grower is ideally feeding what it consumes on a daily basis.

Many growers do not believe that no additional fertilizer have been added at this point, however the plant is continually monitored and if a deficiency was noticed fertilizers would be added but the plant looks good so why add something it does not need.

Also, up to this point there has been an emphasis on water both irrigation and humidity. Pumpkins are 92% water so this is important since a pumpkin is basically a large bag of sugar water.

The plant was growing well and had the correct color so no need to push it and risk speed aging the plant. However, with carbon dioxide enrichment the plant should theoretically consumer more nutrients, but seems the soil can supply those without the need of outside intervention.

There are three main staple fertilizers that I use (see following posts). The Biomin Iron and Copper are used as supplements in season. The iron is typically used early in the season due to the deficiency noticed and the copper is used to help ensure good stem health which may be anecdotal, but the commercial pumpkin growers I work with say there is a correlation.

Water %: https://www.universityofcalifornia.edu/news/10-things-you-probably-didnt-know-about-pumpkins

|

|

|

Monday, June 17

|

View Page

|

|

Nutriculture K-Mag 15-5-30 (plus trace elements)

*Note: The tape is due to a tear in the bag.

Why This Fertilizer?

This fertilizer has a nice ratio of the essential nutrients that are great for what a pumpkin needs. While many would not agree, the phosphorus (middle number) is the maximum I would like to see as this has a tendency to accumulate in the soil and can cause ground water contamination. However, at this ratio, and at the rate it is added (next post) the accumulation is kept to a minimum. The increased ratio of potassium is great and why it is added at this point in the growing season. The plant itself does not need much potassium, but the pumpkin is a heavy potassium sink. Since this is a nutrient that can easily leach adding it early in the season should not be the only addition. The pre-plant application is to ensure good baseline soil potassium level, but now when demand increases it should be added. (Again, as part of the soil-hydro concept.)

Tech Sheet : http://www.plantmarvel.com/wp-content/uploads/2017/07/Tech-Sheet-15-5-30-K-Mag.pdf

|

|

|

Monday, June 17

|

View Page

|

|

Nutriculture K-Mag 15-5-30 (plus trace elements)

Suggested Rates:

*Assuming the starting water is�70ppm (on the 700 scale) or 0.1 EC and has a pH of 6.8